The portable hotbed "Snail" is popular among farmers, due to its small size and ease of use. It can be ordered ready-made or constructed independently from improvised materials. For more information about the features of the factory version and self-installation, read below.

Features and description of the design of the greenhouse "Snail"

The structure under consideration is an arched structure with small dimensions:

- length 2.1–4 m;

- width 1.1 m;

- height 75–85 cm.

Sidewalls are closed tightly. At the end of the vertical roof pipe is the pivot axis, which ensures the opening of one half, as in a bread box. Because of this feature, such a design is also called the “bread box”. The frame is designed for polycarbonate coating.Did you know? Greenhouses began to be used in ancient Rome. True, they were carts in which plants were planted - during the warm time of the day of construction were in the open air, and at night they were brought into the house.

The main function of the designand - protection of seedlings from adverse weather conditions, pests, and maintaining an optimal microclimate in the spring.

- The main advantages of the Snail greenhouse are:

- portability;

- convenience in operation;

- environmental resistance of materials;

- optimal microclimate inside the structure;

- the ability not to fix the structure on the foundation;

- ease of assembly;

- the stability of the greenhouse even with strong gusts of wind.

The disadvantages of the portable design is the inability to cultivate tall plants and the difficulty in performing a garter.

How to make a greenhouse "Snail" with your own hands

One of the main advantages of this model of the greenhouse is the ability to create it with your own hands. This will not require special skills.

Dimensioning and drawing creation

First of all, you should calculate the dimensions of the future design, and build a drawing. It’s better and easier to use ready-made schemes on which the dimensions are displayed.

The length, width and height of the structure can be arbitrary. But it is most convenient to adjust the parameters of the greenhouse to the width of the polycarbonate sheets, which is 2.1 m as a standard. In order to leave less scraps, it is better to make a design with dimensions:

- width 1 m;

- length 2.1;

- height 75 cm.

The lower part of the structure is a rectangular frame 2.1 × 1 m. 2 arcs are attached to this frame. In a narrow part of the base in the center, on both sides, are reinforcing beams. The hinges for the moving part, which is assembled separately, will be fixed to them.

The lower part of the structure is a rectangular frame 2.1 × 1 m. 2 arcs are attached to this frame. In a narrow part of the base in the center, on both sides, are reinforcing beams. The hinges for the moving part, which is assembled separately, will be fixed to them.

Selection of materials and tools

For assembling the frame, a galvanized profile with a cross section of 20 × 20 × 1.2 mm is best suited. The coating is best done from polycarbonate, however, if desired, you can use a reinforced film or extruded polyethylene. In order to sew up such a design, a 6 m wide polycarbonate sheet will be sufficient.

From the assembly tools you will need:Important! The frame of the greenhouse can be made of wood, but this design will have a short service life, so it is better to choose materials for the frame that are resistant to corrosion.

- welding machine;

- drill;

- hacksaw;

- pipe bender;

- level;

- Bulgarian;

- metal circle;

- self-tapping screws.

Choosing and preparing a place for installing a greenhouse

One of the advantages of this greenhouse is the ability to install it anywhere. The main thing is that it should be even and well lit.

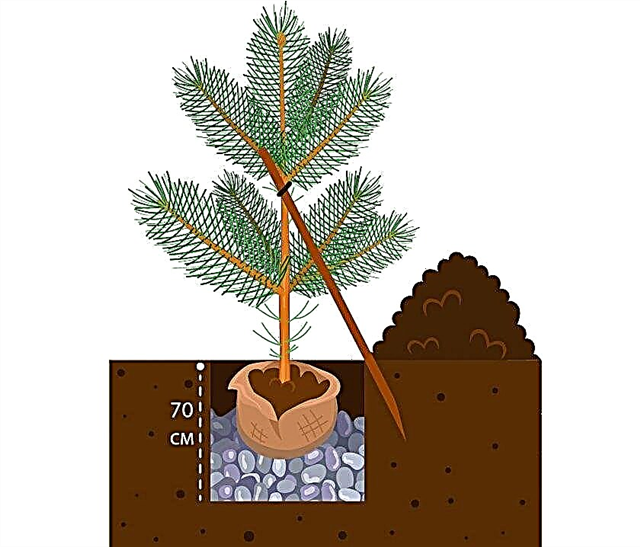

When a site is selected, it is necessary to clean it, and then make a moat with dimensions 2.1 × 1 m. A foundation of wooden beams with a cross section of 15 × 15 cm is installed in this recess. Previously, these beams should be treated with a wood preservative and connected to the frame. Next, the resulting structure is placed in a ditch and begin assembling the frame of the greenhouse.

Step-by-step assembly instructions

First, cut the profile pipe into parts:

- 2 pcs. 2.1 m + 0.5 cm per seam (base details);

- 2 pcs. 1 m + 0.5 cm per seam (base details);

- 2 pcs. 1.95 m for side arches;

- 2 pcs. 75 cm + 0.5 cm per seam for reinforcing side beams on which the hinges will be mounted.

Such blanks will be required for the construction of a blank frame. To create a moving part, you need to cut other workpieces:

- 2 pcs. 1 m for side arches;

- 2 pcs. 2.15 m each;

- 4 things. 52 cm.

Wireframing

First you need to assemble the deaf part of the frame. To do this, you need to weld the base parts into a rectangle, and then fix them on a wooden foundation.

After that, with the help of a pipe bender, lateral arcs are made from blanks of 1.95 m long, welded to the base. Next, reinforcing side beams are welded (details of 75 cm). This assembly of the deaf frame is completed.

The moving part is assembled as follows:Important! Throughout the process of welding parts, use a level so that the structure does not skew.

- Make with the help of a pipe bender half-arc.

- Combine them by welding with long parts.

Required greenhouse skin thickness

When the frame is assembled proceed with polycarbonate coating. Sheets with a thickness of 4 or 6 mm are best suited. Thick polycarbonate has the optimal light transmittance necessary for the normal functioning of plants and allows you to maintain the correct microclimate inside the building.

Thick polycarbonate has the optimal light transmittance necessary for the normal functioning of plants and allows you to maintain the correct microclimate inside the building.

Sheathing should start from the side parts, then move on to the immovable upper part, and only then sew up the movable structure. Polycarbonate is attached to the frame using self-tapping screws.

Comparison of different analogues of greenhouses

An analogue of the considered model of the greenhouse is the "Butterfly". By design, it also represents an arched structure, but instead of one part, both of it open.

By design, it also represents an arched structure, but instead of one part, both of it open.

Compared to the Butterfly, the Snail is simpler to operate, less in weight, which makes it more mobile. In addition, the one-sided opening of the greenhouse provides, at any location on the site, a thermal air cushion in the upper part of the structure. With two-sided opening, even slight cooling can cause the death of plants in the greenhouse, since the fit of the moving parts to the deaf is much less.

Crops suitable for planting in the greenhouse "Snail"

The considered type of greenhouses is suitable for growing undersized vegetables (radishes, herbs, tomatoes, cucumbers, peppers) and flowers. In general, a portable greenhouse is ideal for germinating seeds, followed by transplanting seedlings into open ground. With the independent production of such structures, you can vary the dimensions at your discretion and make them in accordance with the size of the plants that you plan to grow. Then it will be possible to cultivate tall solanaceous crops in them. Also, the model can be used as a winter shelter for perennial heat-loving flowers or dug in the winter to preserve bulbs, cuttings, etc. planting material.

Greenhouse "Snail" is an excellent solution for growing seedlings in early spring, when the weather is still not warm enough. The model has small dimensions, is easy to assemble / disassemble and takes up little space when stored in winter.Did you know? Icelanders organize greenhouses on geysers, which makes it possible to maintain an optimal microclimate in the premises without unnecessary energy costs.