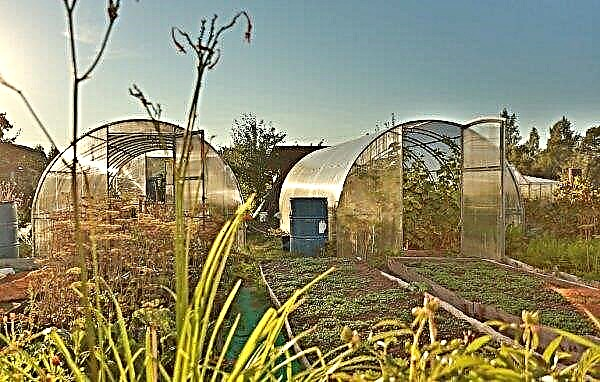

Most gardeners prefer to grow garden vegetables in greenhouse and greenhouse conditions, which is mainly due to the weather characteristics of the regions. But often a gardener who wants to establish a greenhouse is faced with the problem of a lack of space in the garden. The installation of the “Butterfly” greenhouse will help solve this problem, more about the design features of which will be discussed in the article.

Design features

The greenhouse got its name due to the fact that in the open form it really resembles a giant butterfly, which sat down to rest in a summer cottage. The greenhouse is equipped with peculiar leaves that open like the wings of a moth, and thus fresh air and sunlight penetrate into the greenhouse. If you close the greenhouse, it becomes like a cocoon. The parameters of this construction can be different, which allows you to fit it to the size of the selected area.

There is nothing complicated in the gable construction of the greenhouse. Its main components are sides (4 pcs.), Frames (2 pcs.) And a narrowed upper part. For the manufacture of the frame using a metal-plastic or plastic profile. Cover the structure with polycarbonate or polyethylene.Did you know? The first greenhouses before our era were human houses. So, according to archaeologists, the cultivation of plants in houses began in China 5 thousand years ago. The purpose of this lesson is not yet known. Perhaps the plants were grown for use in magic rituals or medical purposes.

For greater convenience, the frames can be divided into sections. Then, if necessary, you can open the desired section and not raise the whole frame. This separation of the frames allows you to make sections in the greenhouse itself, and also makes it possible to grow various crops separately from each other, without involving a large space.

Did you know? The largest greenhouse in the world called Eden was built in the UK. Its area — 22 thousand m².

Advantages and disadvantages of the greenhouse

Summer residents who are looking for the perfect greenhouse are primarily concerned with the question of whether it is comfortable or not. Finding an answer to it will help familiarization with the list of benefits of the Butterfly greenhouse.

And he is different:

Check out

- Universality, which is associated with its parameters: you can choose the sizes for both large and small cottage. This feature makes it possible to rationally use the space and even save it.

- Mobility. The greenhouse structure, if necessary, can easily be decomposed and transferred to another place. There is no need to install the building on the foundation.

- Durability. The greenhouse design withstands wind, a speed of 20 m / s, a 10-centimeter cover of snow.

- Ease of ventilation. Ventilation flaps work thanks to special shock absorbers. This is not only practical and comfortable, but also increases the operational period.

- Economy. Despite all its advantages, buying or building such a construction with your own hands will cost relatively cheap.

- Excellent thermoregulation. The greenhouse ideally retains heat, which creates comfortable conditions for the growth and development of crops, so that they can be planted 1-2 weeks earlier.

- Ease of maintenance. Caring for a greenhouse does not require a lot of effort.

- Protective functions. If the greenhouse is covered with polycarbonate, it will protect your crop from ultraviolet rays.

- The convenience of caring for plants. There is no need to climb inside the structure: thanks to the open leaves, you can get seedlings “from the street” even in the most remote corners.

- Small dimensions of the building they will not obscure the area and crops planted on open ground.

- Among the few shortcomings, it is worth noting:

- Short service life of the hinges that hold the wings (in the case of a purchased greenhouse). This is due to the frequent processes of opening / closing the "Butterfly wings", so the greenhouse must be regularly checked for such breakdowns and, if necessary, repair or replace the hinges.

- The possibility of deformation of the lower arches of the building under the weight of polycarbonate (if it is used as a shelter). Such a minus should be foreseen and additional arc amplifiers should be installed. If a film was used as a coating material, then it can sag.

- Poor, even terrible painting (in the case of a purchased greenhouse). If the manufacturer is unscrupulous, he can use low-quality paints and varnishes, which soon begin to crack and crumble. In this situation, it is necessary to erase such a painting and paint the details of the building yourself.

- Lack or poor quality of mounting holes. This is easily fixed with a file.

Important! Install a greenhouse on a flat area. If the ground is uneven or the site is located in a lowland, then you still need a foundation.

How to choose a greenhouse yourself

Everyone who wants to buy a “Butterfly” should study the criteria for her choice. The first step is to choose the area on which the structure will stand. This is necessary for the correct determination of the dimensions of the greenhouse. Then you should choose a reliable manufacturer with a good reputation, focusing on reviews on the Internet, as well as the advice of familiar gardeners.

If the greenhouse is already in front of you, be sure to pay attention to the materials from which it is made and which will be responsible for the strength and guarantee the duration of operation of the building. Also consider what the frame is painted on and whether there are all the necessary holes in it.

Experienced gardeners give some tips on how to make the right choice:

- Be sure to pay attention to whether the curvature of the arcs coincides with the curvature of the frame to avoid assembly problems.

- It is better to give preference to the polycarbonate coating of the greenhouse, because in the case of the film cracks can form, which will lead to permanent heat loss.

- Inspect the instructions and make sure that all the drawings are clearly drawn and you will not have problems with the assembly.

- Give preference to greenhouses, the details of the frame of which are painted with powder paint with varnish, but not anti-vandal.

Important! If you want to grow crops in cold weather, then select a heated greenhouse.

How to make a greenhouse with your own hands

It is easy to make a “butterfly” with your own hands, especially if you are not averse to crafting, and you succeed. Read more about the stages of construction.

Drawings for construction

The initial stage of building a Butterfly with your own hands is the preparation of drawings. They are necessary in order to perfectly manufacture and fit parts, as well as stock up with the necessary materials, tools and calculate costs.

It is best to use pre-made drawings that can be found on the Internet. The standard height of the greenhouse is 1–1.5 m, the width is 1.3 m. As for the length, you can choose: 2 m or 4 m. If you intend to grow tall crops, the standard height should be done more. The approximate polycarbonate area for a 2-meter length is 2.1 × 4.5 m, and for a 4-meter length it is 2.1 × 7 m.

Materials and Tools

For the "Butterfly" frame, regardless of its size, the following structural components should be prepared:

- 3 crossbars;

- 4 upper stringers with pre-made holes for loops;

- 8 side stringers;

- 4 stringer wing wings;

- 1 intermediate arc;

- 2 end arcs for attaching sheets;

- 6 lugs.

Important! In order to assemble the structure, it is worth stocking up with screws, nuts, self-tapping screws, washers, handles and stops for sashes, hinges and accessories for them, an angular and intermediate bracket.

You should also resolve the issue of materials.

So, the frame, sides and shelter of the "Butterfly" can be built from:

- Tree. This material lends itself well to processing and is readily available. But the operational period is much shorter than the metal one, since the wood can be damaged by the woodworkers, or it will just start to deteriorate and rot.

- Metalwhich differs in reliability, durability and durability. The only minus is the ductility to rust in the absence of painting.

- Glasswhich is great for shelter. You can even use glass taken from old windows, or even window frames. But glass sashes should be handled very carefully, because the durability of their operation depends on the attitude to the material.

- Cell polycarbonate. Ideal for sheltering sashes. It is not as fragile as glass, and can withstand small bumps. It’s not worth experimenting, as polycarbonate can break under the influence of force. It is quite easy to work with such material: it can be cut with an ordinary knife. Moreover, it is not expensive.

- Polyethylene film - One of the most economical options for shelter, but its service life is not long either - it is easy to damage the film.

To create a greenhouse, you need to prepare the following tools:

- hacksaw for cutting metal or wood;

- hammer;

- roulette wheel;

- screwdriver;

- glass cutter;

- scissors;

- knife;

- drill;

- circular saw.

Important! If you are making a metal frame, then stock up on a welding machine. In addition, you must have welder skills. Otherwise, either abandon the idea of making a “Butterfly” with your own hands, or contact a familiar welder.

Frame preparation and installation

The procedure is not complicated and consists of the following steps:

- Before you begin installing the frame, you need to prepare a place for the greenhouse. The site should be as flat and clean as possible. The upper subgrade can be removed if it is dirty.

- If the ground is uneven, then it is necessary to put the structure on the foundation. To do this, you will have to dig a trench corresponding to the perimeter of the future greenhouse. Put a layer of waterproofing inside the trench. It is also necessary to reinforce its corners and only then pour a liquid solution of sand and cement. Part of the foundation, which protrudes above the ground (basement), is laid out with bricks.

- When the site with the foundation is ready, you can proceed directly to the assembly of the frame. This must be done in strict accordance with the drawings. Metal parts are connected either by welding, or by bolts and screws. The frame must be firmly fixed on the basement. The main fastener is the M5 (M4) × 30 screw.

- The frame must be processed: metal - anti-corrosion agent, wood - antiseptic and varnish.

- After processing, on the top of the frame, a central beam is installed, to which the sashes will be attached, or rather holes for the hinges will be drilled. Butterfly wings should be firmly attached to the ends of the frame, pre-connected with special profiles.

- Then you need to do the cutting of the required size polycarbonate with a circular saw. Finished sheets are fixed to the frame using self-tapping screws, thermowells and fasteners with gaskets. Polycarbonate sheets must be fixed so that their honeycombs are located vertically to the ends and flaps of the greenhouse.

- Each joint of the frame structure must be treated with silicone hermetic.

- In order to keep the sash in the open position, the sides of the greenhouse are strengthened with special supports.

- The final stage of the assembly is the installation of handles on the wings where it is convenient for you.

Video: Installation of the Butterfly greenhouse

The required thickness of the skin

Since the “Butterfly” refers to small greenhouse buildings, the optimum thickness of the skin for it is 4 mm. To make sure that you are offered quality polycarbonate, focus on weight. The weight of a standard sheet of polycarbonate (2.1 m × 6 m) with a thickness of 4 mm is 10 kg. If the seller offers sheets with much lower indicators of weight, then there is every reason to assume that you want to sell a fake.

As you can see, in order to collect a good harvest of your favorite crops, there is absolutely no need to spend money on expensive and impressive greenhouses. It is enough to purchase or make a Butterfly greenhouse with your own hands. Such a construction will completely satisfy you with its parameters, economy and versatility.Important! One installation does not end there. The greenhouse must be constantly looked after: tinted, grease the hinges.